The stud is designed to connect various parts, parts of structures with pre-prepared smooth and threaded holes: these can be nodes of machine mechanisms, fixing ceilings, frames, hanging boxes, etc. A fully threaded axle is very widely used in construction; this type of connection allows not only to securely fix structures, but also to make disconnection as problematic as possible. Standardly such a product is produced in lengths of 1m, 2m, 3m. The integrity of the design extends the period of safe operation.

The length and thickness of the stud for each object is calculated depending on the load that will subsequently be placed on it. It is also necessary to take into account the aggressiveness of the environment and, in case of its high degree, only studs with a protective layer should be used. For corrosion protection of the stud, as well as on other types of hardware, protection is applied by means of electrolysis, the most used galvanic coating is zinc.

In cases where it is necessary to fasten and securely fix parts between which there is a distance, the stud is placed in the prepared holes, and nuts of the corresponding thread are screwed onto its ends. Moreover, the thread at the ends of the stud can be versatile, and differ in step size and diameter. The stud can be made according to completely individual drawings.

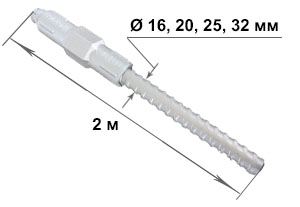

These technical conditions (TU) apply to studs made from high-quality hot-rolled steel of a screw profile.

Screw profile studs are used as fasteners in the assembly and installation of metal structures, prefabricated reinforced concrete structures in civil and industrial construction, and can also be used in other sectors of the economy.

The design and dimensions of the screw profile studs are established by working drawings.

The construction of the screw profile studs in terms of the impact of climatic factors corresponds to category IV according to GOST 15150-69 for operation in a temperate climate at an ambient temperature of minus 40°C to plus 45°C.

General provisions

Screw profile studs must comply with the requirements of these specifications.

The design and nominal dimensions of the studs made of high-quality hot-rolled steel of a screw thread profile according to TU 25.11. 23.110 -008 -83936644-2018 (hereinafter referred to as screw profile studs) are determined by working drawings. If necessary, screw profile studs can be manufactured in other sizes in accordance with the technical requirements set forth in the Customer's Agreement as agreed by the parties.

These Specifications (hereinafter referred to as TU) apply to carbon steel screw profile studs made from high-quality hot-rolled screw profile for steel building structures of various types (solid-walled, sheet, combined, etc.). These specifications do not apply to structures related to special technological equipment (railway and road bridges, gas tanks, equipment operating in aggressive environments, etc.).

Screw profile studs can be operated at temperatures up to minus 400C. 1.5. These specifications apply to carbon steel screw profile studs with a diameter of 14 to 40 mm.

Appearance

The surface of the screw profile studs must be clean, without traces of corrosion and mechanical damage affecting the strength characteristics of the product.

Permissible surface defects of the studs (cracks of various nature, rolled bubbles, flaws, ripples, folds, chips, damage to the profile and profile tops, tool marks, as well as burrs) in accordance with TU 25.11. 23.110 -008 -83936644-2018 p.4.3.8

Main parameters and dimensions

The design, dimensions of the carbon steel screw profile studs, made from high-quality hot-rolled steel of the screw profile, are established in these specifications.

Dimensional tolerances and shape tolerances of studs in accordance with the requirements of TU 25.11. 23.110 -008 -83936644-2018, taking into account changes in limit deviations.

The geometrical parameters of the screw profile studs shall comply with Table 1.

|

Nominal

diameter |

Screw profile stud parameters |

||||||||

|

dв мм |

h mm

not less than |

dг мм |

t mm

not less than |

L мм |

|||||

|

nom. |

dev. |

nom. |

dev. |

nom. |

dev. |

nom. |

dev. |

||

|

14 |

13,5 |

+0,1 - 0,2 |

0,6 |

±0,1 |

13,0 |

±0,2 |

4,0 |

±0,2

|

150-11700 |

|

15 |

14,7 |

+0,2 -0,1 |

1,0 |

0,2 -0,1 |

14,6 |

6,0 |

|||

|

16 |

15,9 |

+0,15 - 0,2 |

+0,1 - 0,2 |

15,7 |

|||||

|

15,6 |

±0,2 |

±0,2 |

15,4 |

||||||

|

18 |

17,4 |

17,1 |

|||||||

|

20

|

19,4 |

19,0 |

7,0 |

||||||

|

19,4 |

19,0 |

||||||||

|

19,4 |

19,0 |

||||||||

|

22 |

21,3 |

20,8 |

|||||||

|

21,3 |

20,8 |

||||||||

|

25 |

24,3 |

+0,5 -0,15 |

23,8 |

8,0 |

|||||

|

28 |

26,3 |

±0,2 |

25,8 |

9,0 |

|||||

|

32 |

31,6 |

±0,2 |

31,2 |

11,0 |

|||||

|

36 |

35,6 |

35,2 |

13,0 |

||||||

|

40 |

39,6 |

39,2 |

14,0 |

||||||